[et_pb_section bb_built=”1″ admin_label=”section”][et_pb_row admin_label=”row”][et_pb_column type=”4_4″][et_pb_text admin_label=”Text” background_layout=”light” text_orientation=”left” use_border_color=”off” border_color=”#ffffff” border_style=”solid”]

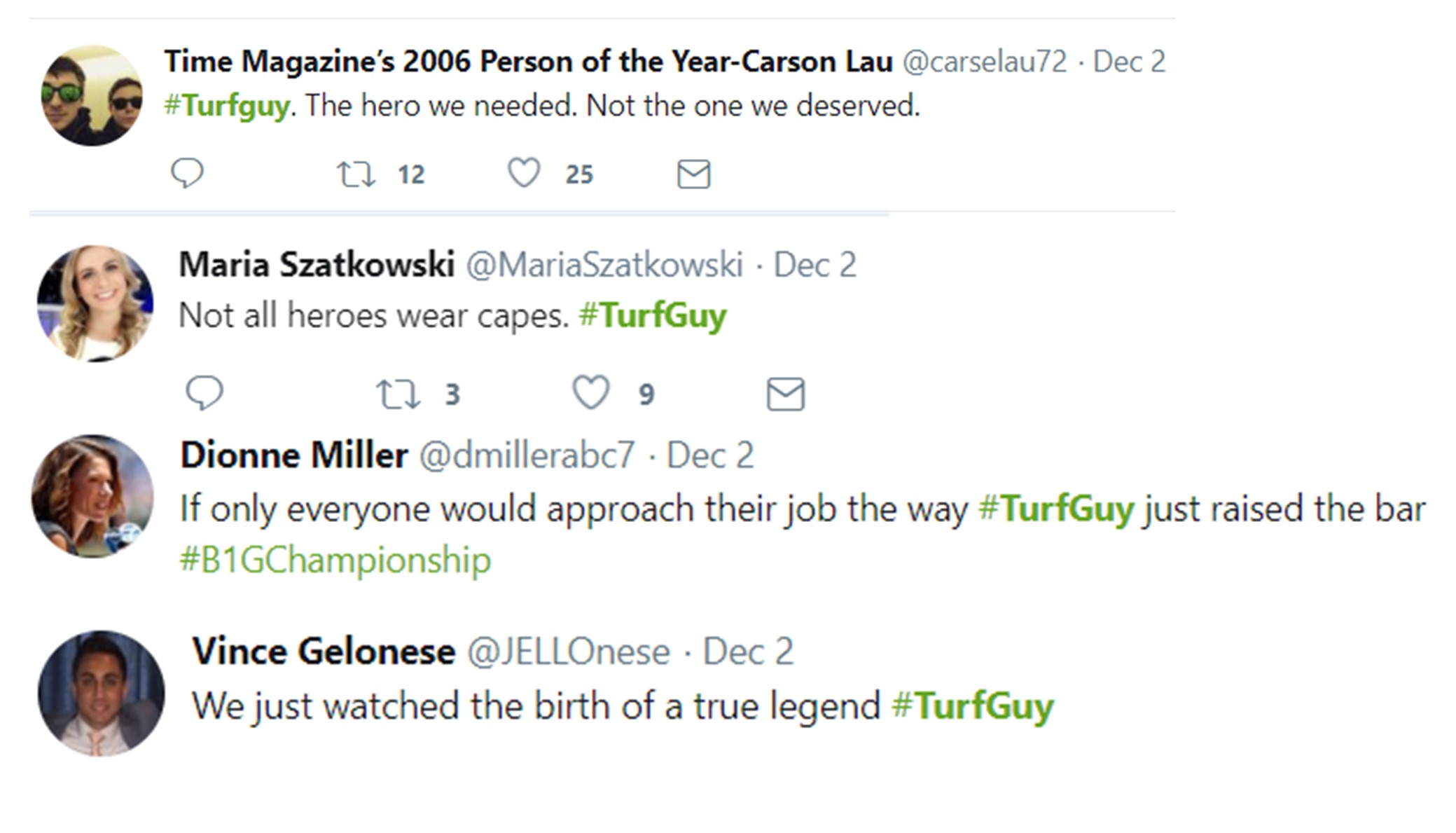

Much attention was paid to the very lengthy delay that ensued when the turf seemingly tore under players’ feet at the goal line. Erik Harlow, groundskeeper and social media sensation, feverishly reseamed the turf and replaced the infill in front of the eyes of the whole world. Tweets quickly heralded Mr. Harlow a “#turf hero” ….  and he did a superb job under intense scrutiny to get the field at Lucas Oil Stadium back into playable condition. However, given the time constraint and intense pressure to resume play, it made it impossible to fully complete the repair on the balance of the head seam extending into the endzone. While some people think “Turf is turf,” the reality is much more nuanced and complex, with the entire design philosophy of a turf manufacturer creating a big impact on the field, players, and stadium operations. That was clear at the Big 10 Championship! So what really happened to the turf? And how can stadiums avoid this sort of public debacle and safety hazard in the future? To be clear, the turf at Lucas Oil Stadium is NOT AstroTurf. But, AstroTurf can shed a little light on the issue, having earned a reputation for excellence in the niche conversion market, with high-profile removable fields installed over the last several decades at venues like the Alamodome, Rogers Centre, NRG Stadium, Edward Jones Dome, and more.

and he did a superb job under intense scrutiny to get the field at Lucas Oil Stadium back into playable condition. However, given the time constraint and intense pressure to resume play, it made it impossible to fully complete the repair on the balance of the head seam extending into the endzone. While some people think “Turf is turf,” the reality is much more nuanced and complex, with the entire design philosophy of a turf manufacturer creating a big impact on the field, players, and stadium operations. That was clear at the Big 10 Championship! So what really happened to the turf? And how can stadiums avoid this sort of public debacle and safety hazard in the future? To be clear, the turf at Lucas Oil Stadium is NOT AstroTurf. But, AstroTurf can shed a little light on the issue, having earned a reputation for excellence in the niche conversion market, with high-profile removable fields installed over the last several decades at venues like the Alamodome, Rogers Centre, NRG Stadium, Edward Jones Dome, and more.

So why would a company put in a head seam at all? It all has to do with the weight of the turf. If the turf and infill are too heavy, it can become extremely difficult to roll up a full 160’ wide panel that would be required to run sideline to sideline. We believe the field at Lucas Oil Stadium is a heavyweight infill system, with 9+ lbs of sand and rubber in the turf. Part of the reason that AstroTurf has always played well in the convertible turf market is its historical emphasis on “More Fiber, Less Fill.” Putting in turf with more fiber and less fill enables us to avoid headseams altogether and ensure that the only seams that run perpendicular to the body of the field are outside the playing surface. Turf is manufactured in 15’ wide panels. So, consider the panel weights in heavy fiber weight systems versus heavy infill weight systems:

| Heavy fiber Weight System (AstroTurf RootZone 3D System) | Heavy Infill Weight System (like Lucas Oil Stadium) | |

| Turf weight per sq. ft. | .4 lbs | .27 lbs |

| Infill weight per sq. ft. | 5 lbs | 9 + lbs |

| Total weight per sq. ft. | 5.4 lbs | 9.27 lbs |

| Panel square feet | 15’ x 160’ = 2400 square feet | 15’ x 160’ = 2400 square feet |

| Total Panel Weight | 12,960 + lbs | 22,248 + lbs |

That’s a lot more weight to have to roll up in a single panel!

In permanent installations, which is a much larger segment of the market than conversion fields, the reasons for our “More Fiber, Less Fill” approach are numerous:

Safety—Our heavy fiber weight system includes a RootZone®– which is a fiber matrix that curls down and acts like a net to encapsulate the infill and reduce infill migration and splash. When the infill is better held in place, that means:

- More consistent shock absorption when players fall on the field

- More consistent footing

- Less infill compaction and rotational resistance on lower extremities – which has been demonstrated by independently funded testing at Michigan State University

ROI—More fiber on the front end means a longer field life, since the quality and content of the fiber directly determines when a field needs to be replaced!

Aesthetics—A field that has more fiber in a dense matrix looks more plush than a sparse turf system. Plus, you have less of that unattractive fly-out from rubber on the field as players cut and slide.

All of these benefits also apply to the removable turf systems of course. Plus, with the RootZone, you have much less infill loss each time the turf is rolled. This video shows the turf being rolled up inside a pit at the Edward Jones Dome – imagine doing that without a RootZone!

If you’re a facility looking to upgrade – contact AstroTurf. We know that these systems are a lot more involved than a “green side up” approach, and we can help!

About AstroTurf® For athletes and sport enthusiasts, AstroTurf® has redefined the way the game is played. The brand offers advanced, state-of-the-art, multi-sport and specialized synthetic turf systems with proprietary engineered technologies. A growing number of high schools, colleges, professional sports teams and municipalities continue to select AstroTurf-branded products for their premium quality, technical superiority, and safety. To learn more, visit AstroTurf’s newly redesigned website at www.astroturf.com.

[/et_pb_text][/et_pb_column][/et_pb_row][/et_pb_section]